Direct Gas Fired-Indirect Gas Fired

There are two primary gas-fired AHU types: direct gas-fired and indirect gas-fired.

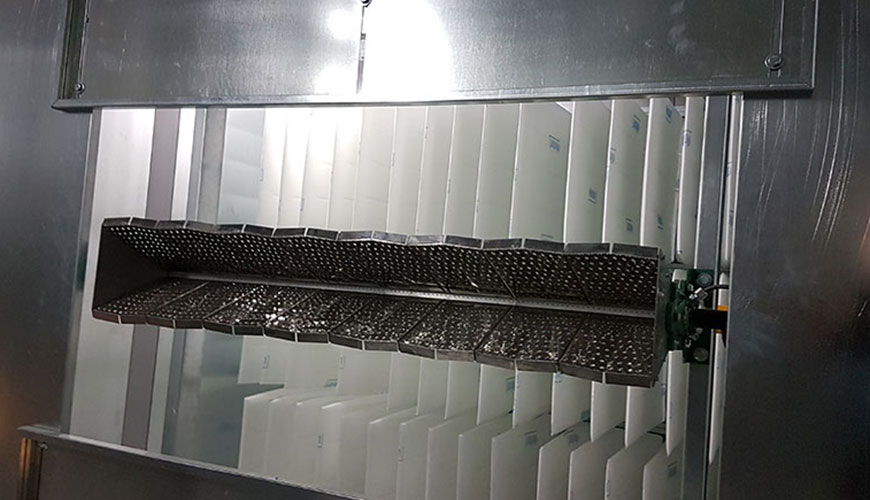

Direct gas-fired. A direct gas-fired AHU has a gas burner installed directly in the outside makeup-air stream. The products of combustion (carbon dioxide [CO2], carbon monoxide [CO], nitrogen dioxide [NO2], aliphatic aldehydes, and water vapor) are discharged into the makeup-air stream and supplied to the building or process.

Advantages of direct gas-fired AHUs include higher energy efficiency, lower installation cost, free humidification, and inherent freeze protection.

Good direct-gas-fired-AHU applications include facilities/processes that have high exhaust/infiltration airflows, large open spaces with few smaller spaces, and no low-humidity-control requirements. Direct gas-fired AHUs commonly are used in commercial kitchens. Other commercial facilities that might benefit from utilizing direct gas-fired AHUs include fitness centers/gyms, enclosed stadiums, auditoriums, large retail stores, car dealerships, airport terminals, and laboratories.

Indirect gas-fired. An indirect gas-fired AHU has a sealed combustion chamber in which all products of combustion are discharged through a flue to the outside environment and no products of combustion are discharged within the makeup air supplied to the building.